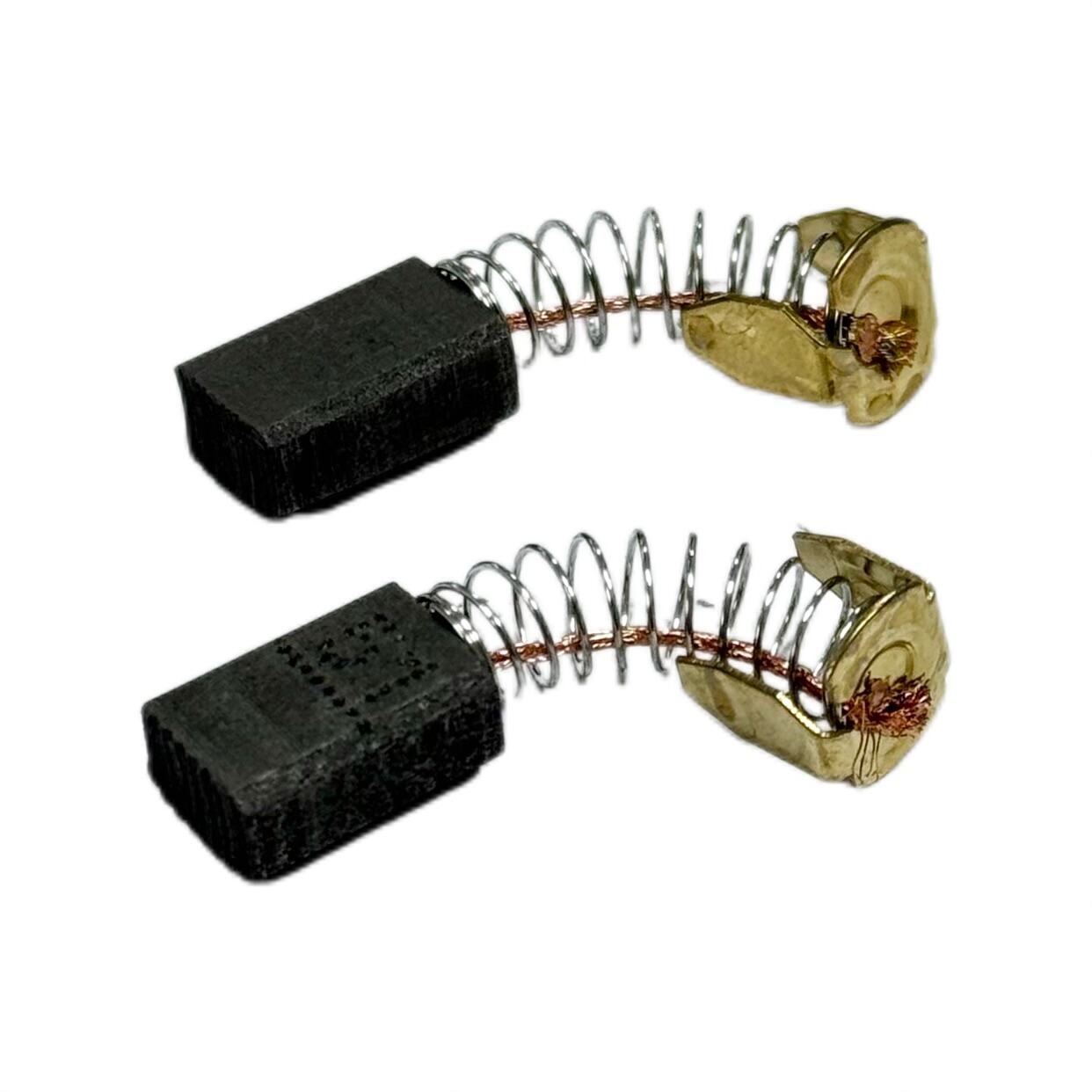

brush carbon motor

A brush carbon motor represents a fundamental component in electrical engineering, combining reliability with straightforward operation. This motor type utilizes carbon brushes to conduct electrical current between stationary and rotating parts, enabling continuous motion. The design incorporates a commutator, which reverses current direction periodically, maintaining consistent rotational movement. These motors feature carbon brushes made from high-grade graphite materials, ensuring optimal conductivity and wear resistance. The brushes maintain constant contact with the commutator, creating a reliable electrical connection that powers the armature. Modern brush carbon motors incorporate advanced features like improved brush materials, enhanced commutation systems, and optimized electromagnetic designs. They find extensive applications in household appliances, power tools, automotive systems, and industrial machinery. The motor's ability to provide high starting torque, coupled with its cost-effective design, makes it particularly suitable for applications requiring variable speed control. These motors operate effectively across various voltage ranges and can be easily integrated into both simple and complex mechanical systems. Their robust construction ensures reliable performance in demanding environments, while their straightforward maintenance requirements contribute to their continued popularity in various applications.