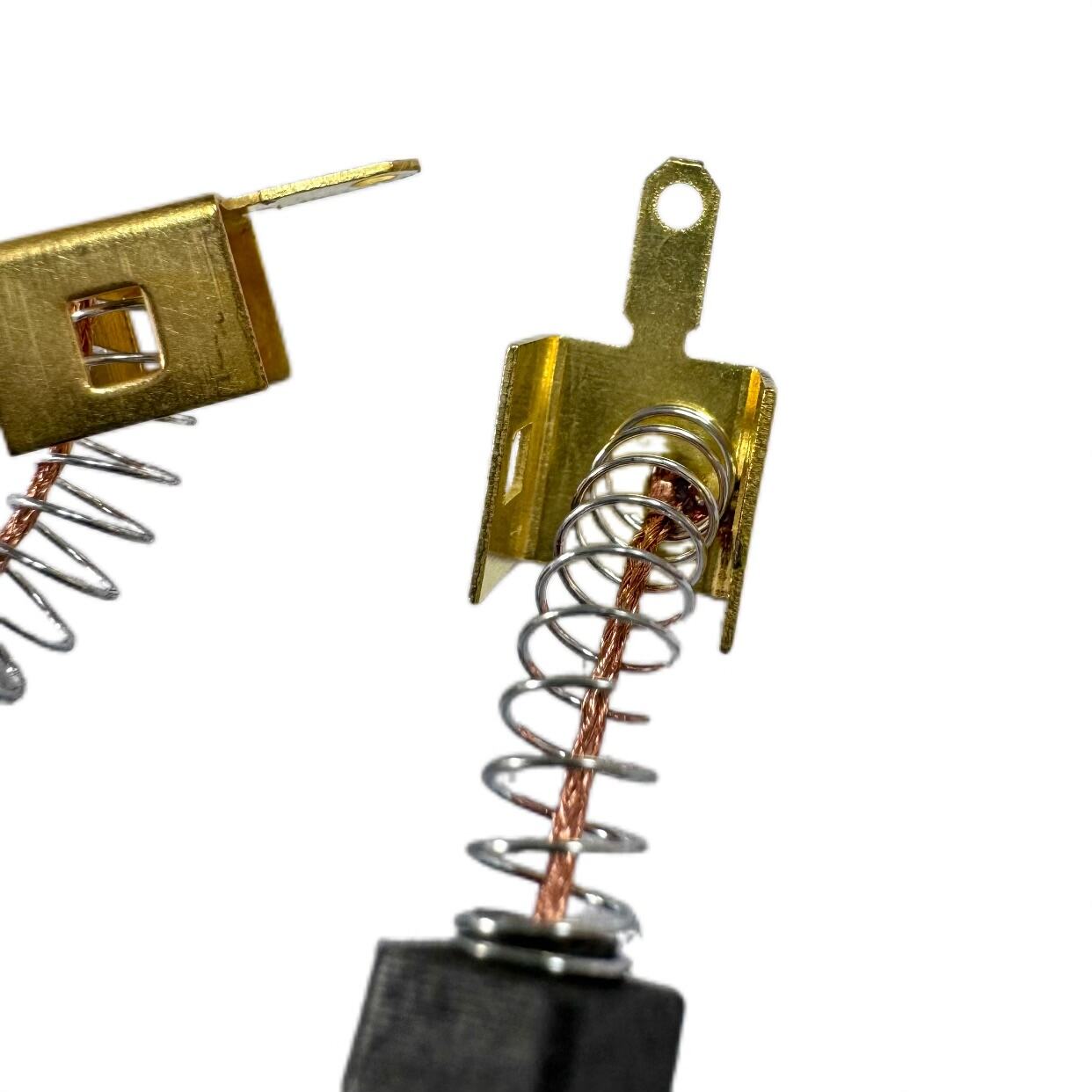

makita carbon brushes

Makita carbon brushes are essential components that play a crucial role in the functionality and longevity of power tools. These precision-engineered parts are designed to conduct electrical current between the stationary and rotating parts of electric motors, ensuring consistent power delivery and optimal performance. Made from high-grade carbon materials, Makita brushes feature specialized compositions that provide excellent conductivity while maintaining durability under high-stress conditions. The brushes are manufactured to exact specifications, ensuring perfect fit and compatibility with various Makita power tools, including drills, grinders, and saws. Their advanced design incorporates auto-cut technology that automatically disconnects power when the brushes wear down to a critical level, protecting the motor from potential damage. The carbon composition is carefully formulated to achieve the ideal balance between hardness and conductivity, resulting in minimal wear and extended service life. These brushes also feature pressure springs that maintain consistent contact with the commutator, ensuring stable power transfer and reducing sparking during operation. The precision-engineered design includes wear indicators that allow users to monitor brush condition and plan maintenance effectively.