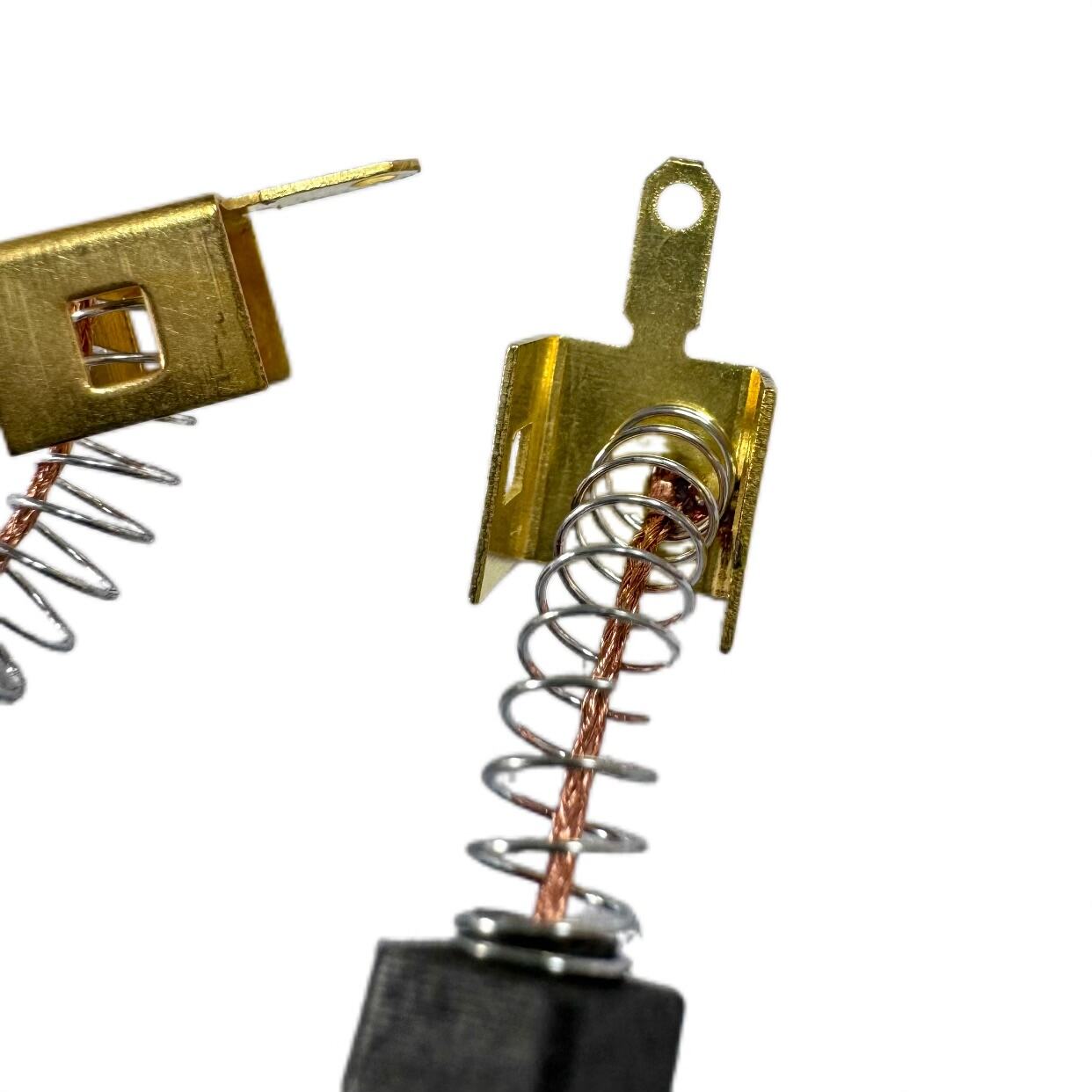

carbon brush for mixer

A carbon brush for mixer is an essential electrical component that facilitates the transfer of electrical current between stationary and rotating parts in mixing equipment. These specialized brushes are crafted from high-grade carbon materials, engineered to provide optimal conductivity while maintaining durability under continuous operation. The design incorporates precise dimensions and specific carbon compositions to ensure consistent performance in various mixing applications. These brushes feature self-lubricating properties that reduce friction and wear during operation, extending the lifespan of both the brush and the mixer's motor. The carbon composition is carefully selected to balance conductivity with wear resistance, making it suitable for both industrial and commercial mixing equipment. Advanced manufacturing processes ensure uniform density and structural integrity, which are crucial for maintaining stable electrical contact and preventing motor damage. The brush holder assembly is designed for easy installation and replacement, minimizing maintenance downtime. Modern carbon brushes for mixers often include safety features such as wear indicators and protective coatings that enhance their reliability and user-friendly nature.