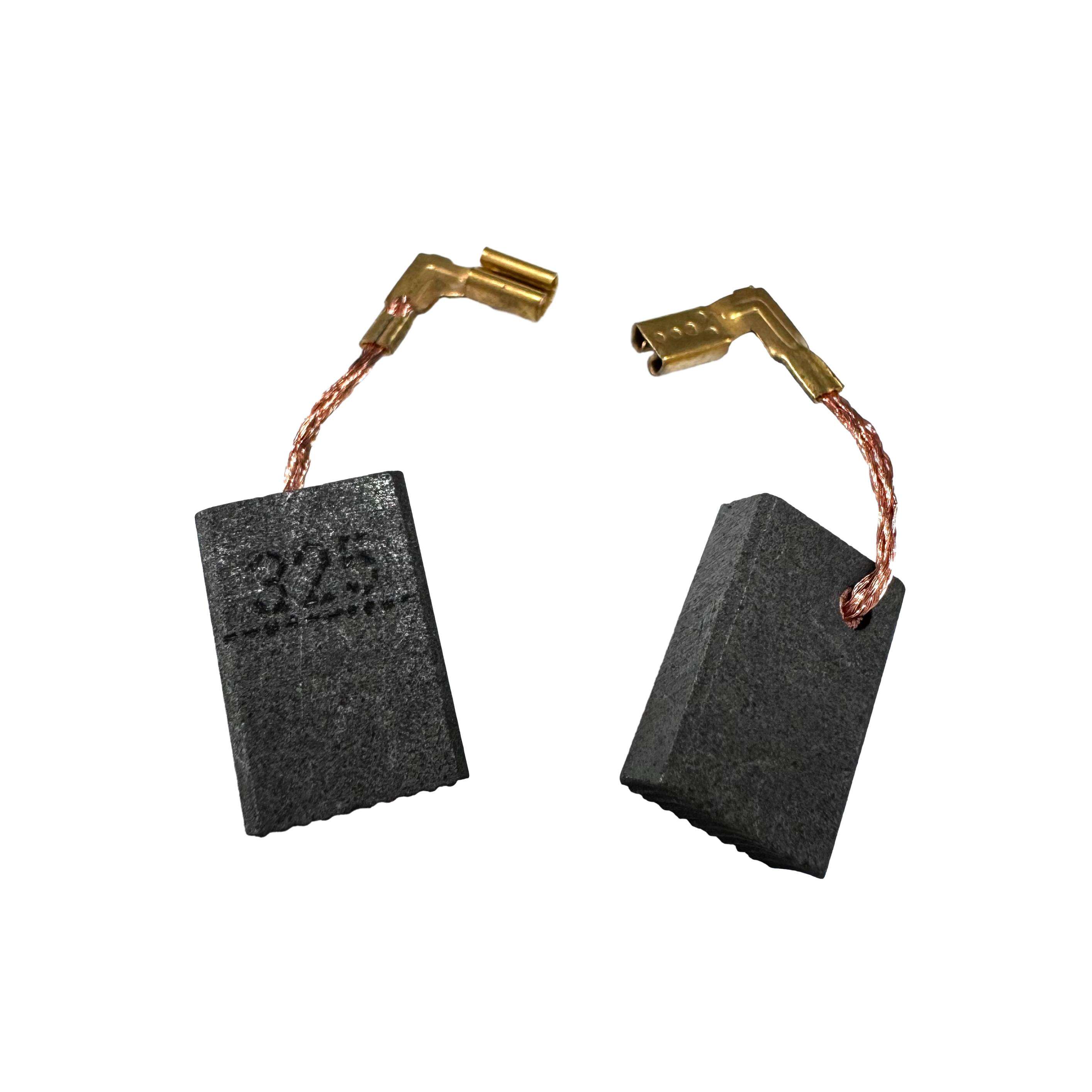

carbon brush for makita

The carbon brush for Makita power tools is an essential component that ensures optimal electrical conductivity and motor performance. These precision-engineered components are designed to provide consistent power transfer between stationary and rotating parts within Makita power tools. Made from high-grade carbon compounds and copper materials, these brushes offer exceptional durability and conductivity. The brushes feature precise dimensions and specifications that match original Makita requirements, ensuring perfect fit and functionality. They incorporate advanced wear-resistant technology that extends their operational lifespan while maintaining consistent performance. The carbon composition is specially formulated to reduce sparking and minimize motor wear, contributing to the overall longevity of the power tool. These brushes are compatible with a wide range of Makita tools, including drills, grinders, saws, and sanders. They feature an auto-stop function that prevents motor damage by discontinuing operation when the brush reaches its wear limit. The installation process is straightforward, with clear indicators for proper positioning and replacement timing. Each brush is quality tested to meet stringent performance standards and ensure reliable operation under various working conditions.