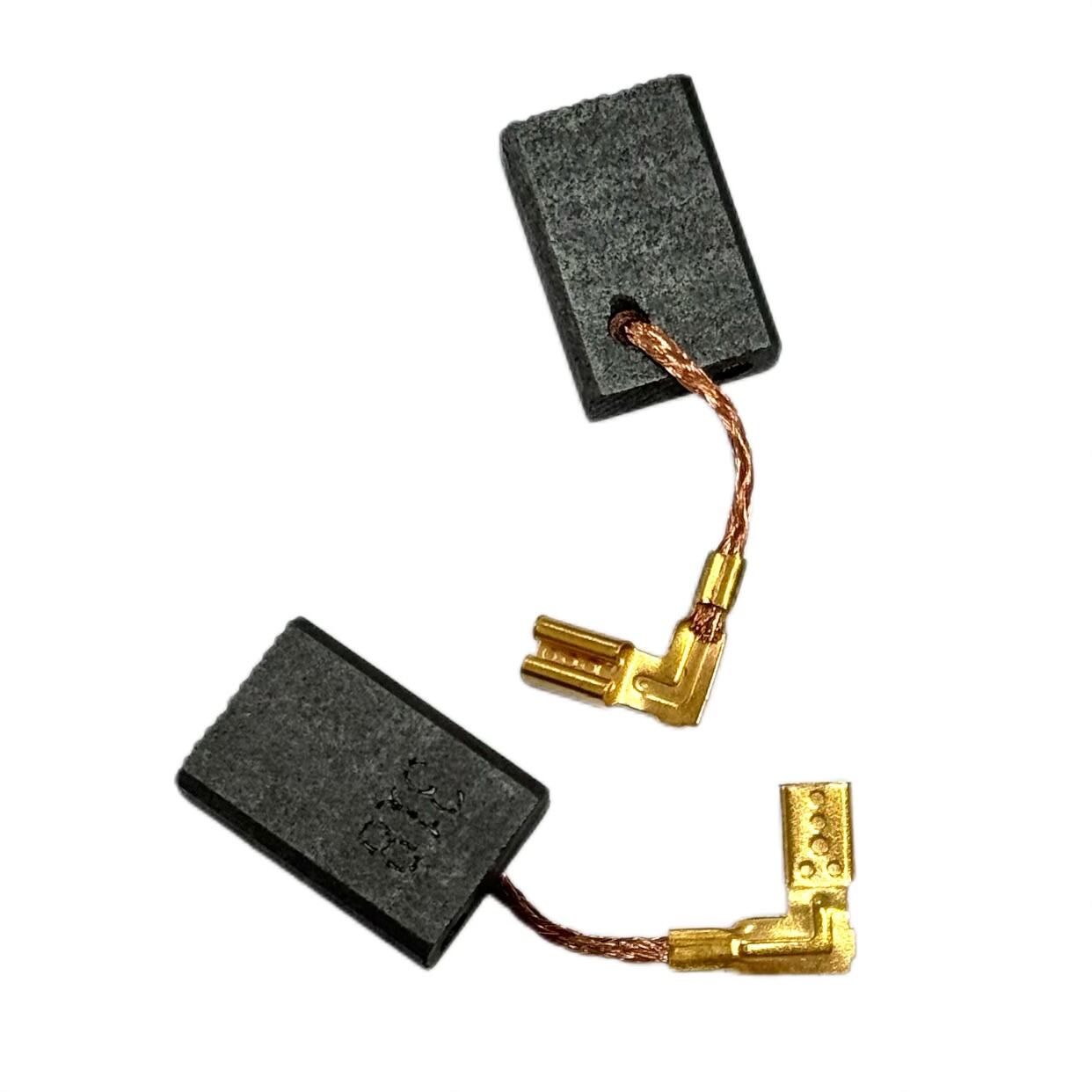

bosch carbon brushes

Bosch carbon brushes represent a crucial component in electric motors and power tools, serving as the vital link between stationary and rotating parts. These precision-engineered components conduct electrical current from the fixed power source to the moving armature, ensuring consistent power delivery and optimal motor performance. Manufactured with high-grade carbon and copper materials, Bosch carbon brushes feature advanced composition technology that delivers superior conductivity while minimizing wear and friction. Their unique design incorporates self-adjusting spring mechanisms that maintain constant pressure against the commutator, guaranteeing reliable electrical contact throughout the brush's lifecycle. These brushes are specifically engineered to meet the demanding requirements of both professional and consumer-grade power tools, offering extended service life and consistent performance under various operating conditions. With precise dimensional tolerances and quality construction, Bosch carbon brushes provide smooth operation while preventing excessive sparking and reducing electromagnetic interference. Their application spans across numerous power tools, including drills, grinders, sanders, and saw motors, making them an essential component for maintaining and repairing electrical equipment.