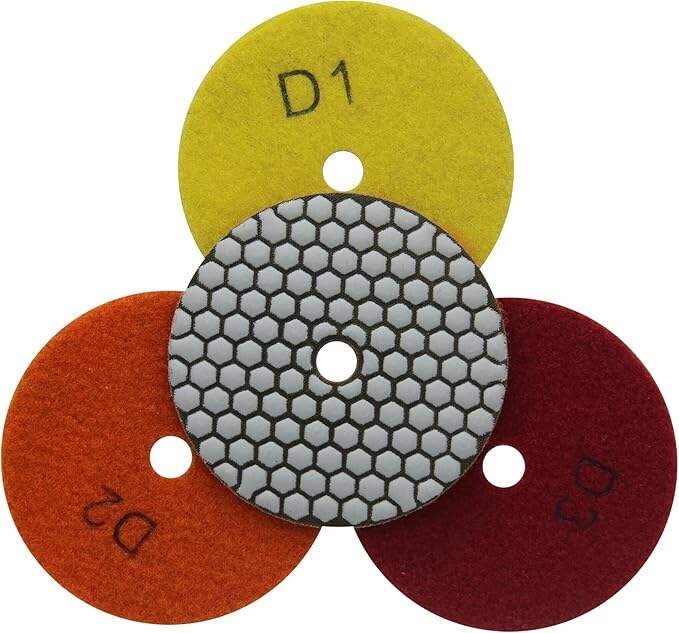

Understanding the Critical Role of Backing Pads in Surface Preparation Surface preparation professionals and DIY enthusiasts alike rely heavily on backing pads as essential components in their sanding and polishing operations. These versatile tools s...

VIEW MORE

Essential Guide to Professional Polishing Support Systems Professional detailing and polishing work demands the right tools for outstanding results. At the heart of any polishing system lies the backing pad - a crucial component that can make or brea...

VIEW MORE

Understanding the Essential Role of Backing Pads in Modern Surface Finishing The world of surface finishing and polishing has evolved significantly, making the selection of proper equipment more crucial than ever. At the heart of any successful finis...

VIEW MOREEssential Safety Guidelines for Power Tool Attachment Usage Working with power tool accessories requires skill, knowledge, and careful attention to detail. Whether you're a professional contractor or a DIY enthusiast, using these attachments correctl...

VIEW MOREEssential Guide to Power Tool Accessory Selection Whether you're a professional contractor or a passionate DIY enthusiast, selecting the right power tool accessories can make the difference between a project's success and frustration. These vital com...

VIEW MOREMaximizing Performance and Safety with Premium Tool Attachments When it comes to power tools, the accessories you choose can make the difference between a mediocre result and a masterpiece. High-quality power tool accessories represent more than just...

VIEW MORE

Understanding the Modern Convenience of Keyless Drill Chucks The evolution of power tools has brought us many innovations, and the keyless chuck stands as one of the most significant improvements in drill design. This ingenious mechanism has transfor...

VIEW MORE

Understanding the Evolution of Modern Drill Chucks The world of power tools has seen remarkable innovations over the decades, and one of the most significant advancements has been the development of the keyless chuck. This revolutionary tool holding ...

VIEW MORE

Understanding the Essential Components of Construction Hammers When it comes to construction work, having the right tool for the job is crucial, and hammers are no exception. The various hammer parts play distinct roles in making each type suitable f...

VIEW MORE

Understanding Common Hammer Issues and Their Solutions Every DIY enthusiast and professional craftsperson knows that a hammer is only as good as its parts. When hammer parts begin to show signs of wear or damage, it can significantly impact your work...

VIEW MORE

Understanding the Foundation of Surface Preparation Tools In the world of surface preparation and finishing, backing pads serve as the critical interface between power tools and abrasive discs. These essential components play a vital role in ensuring...

VIEW MORE

Understanding the Essential Role of Backing Pads in Professional Sanding Achieving a flawless finish in any sanding project relies heavily on selecting the appropriate backing pad. This crucial component serves as the foundation between your power to...

VIEW MORE