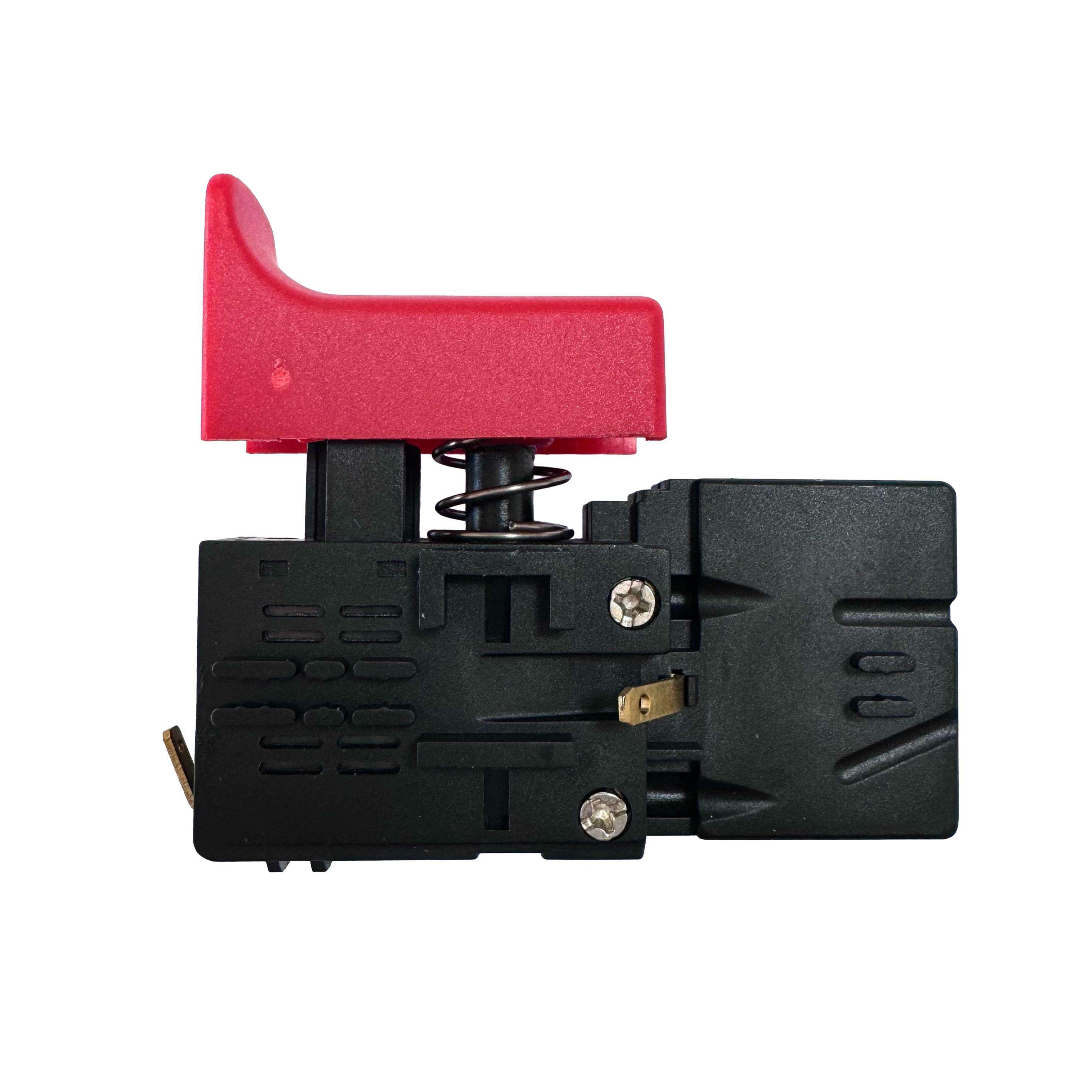

drill switch manufacturer

A drill switch manufacturer specializes in producing high-quality, reliable switching mechanisms that are essential components in power drills and other power tools. These manufacturers employ advanced engineering processes and state-of-the-art technology to create switches that control speed, direction, and power output. Their production facilities utilize precision manufacturing equipment to ensure consistent quality and durability in every switch produced. The switches are designed to handle various voltage requirements and operating conditions, incorporating safety features such as overload protection and thermal cutoffs. These manufacturers typically offer customization options to meet specific client requirements, whether for professional-grade tools or consumer-level products. They maintain strict quality control measures throughout the production process, from raw material selection to final testing. The switches are engineered to provide smooth operation, precise control, and long service life, making them ideal for both corded and cordless drill applications. Many manufacturers also invest in research and development to improve switch technology, focusing on enhanced durability, improved heat resistance, and better ergonomic design. They serve various sectors including power tool manufacturers, industrial equipment producers, and aftermarket parts suppliers.