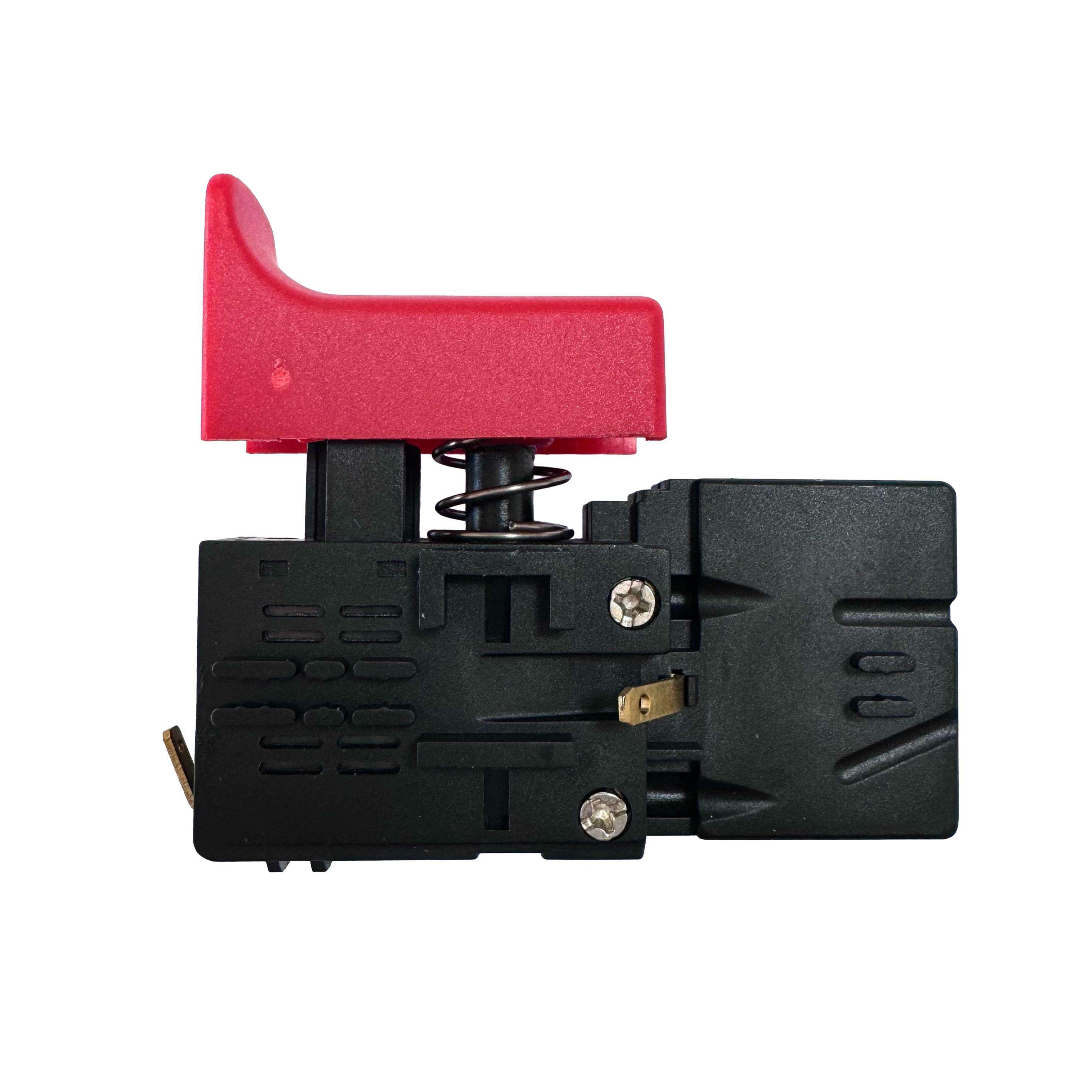

drill switch

A drill switch serves as a crucial control mechanism in power drills, enabling users to manage the tool's operation with precision and ease. This essential component allows operators to turn the drill on and off, control variable speeds, and switch between forward and reverse rotations. Modern drill switches incorporate advanced electronic features that provide enhanced functionality, including speed regulation systems that maintain consistent RPMs under varying loads. The switch assembly typically consists of a trigger mechanism, direction control lever, and internal circuitry that manages power distribution. These switches are designed with durability in mind, featuring robust construction to withstand frequent use and harsh working conditions. They often include safety features such as lock-on buttons for continuous operation and electronic brake systems for immediate stoppage. The versatility of drill switches makes them suitable for various applications, from DIY home projects to professional construction work. Advanced models may also include built-in LED indicators for battery status and torque settings, making them more user-friendly and efficient.