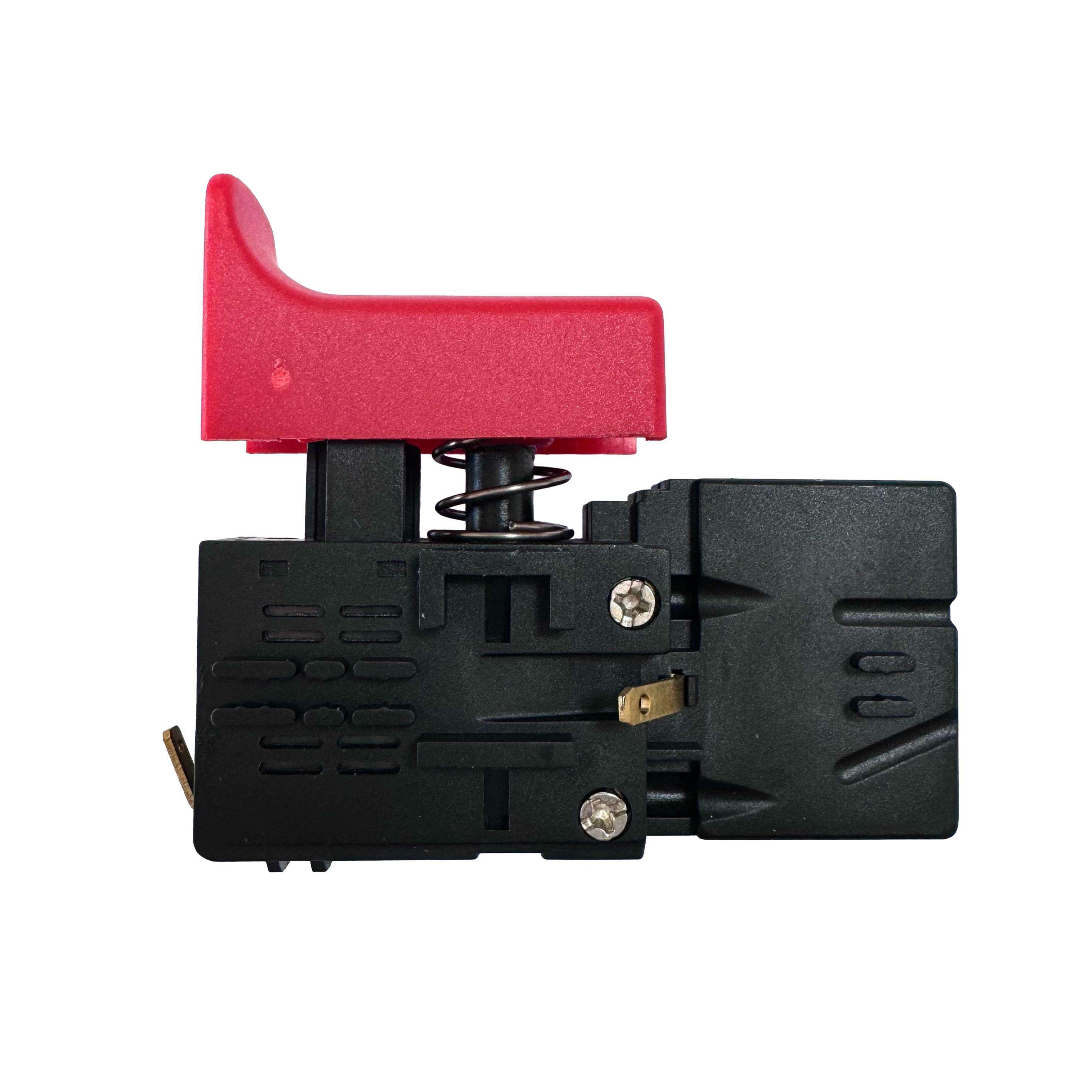

drill machine reverse forward switch

The drill machine reverse forward switch is a crucial component that enables bidirectional control of rotary power tools. This essential mechanism allows users to change the rotation direction of the drill bit with a simple toggle, making it invaluable for various drilling and fastening applications. The switch typically features a robust design with clear directional indicators, ensuring intuitive operation and reliable performance. Modern reverse forward switches incorporate advanced safety features, including a center-lock position that prevents accidental activation during transport or storage. The mechanism operates through a sophisticated electrical system that reverses the motor's polarity, enabling seamless transitions between clockwise and counterclockwise rotation. This versatility proves particularly useful when dealing with different materials and applications, from driving screws to removing stubborn fasteners. The switch's design prioritizes durability and ease of use, often featuring ergonomic placement for comfortable operation during extended use. Additionally, many contemporary models include dust-proof sealing and reinforced internal components, extending the tool's lifespan and maintaining consistent performance in challenging work environments.