dewalt grinder parts

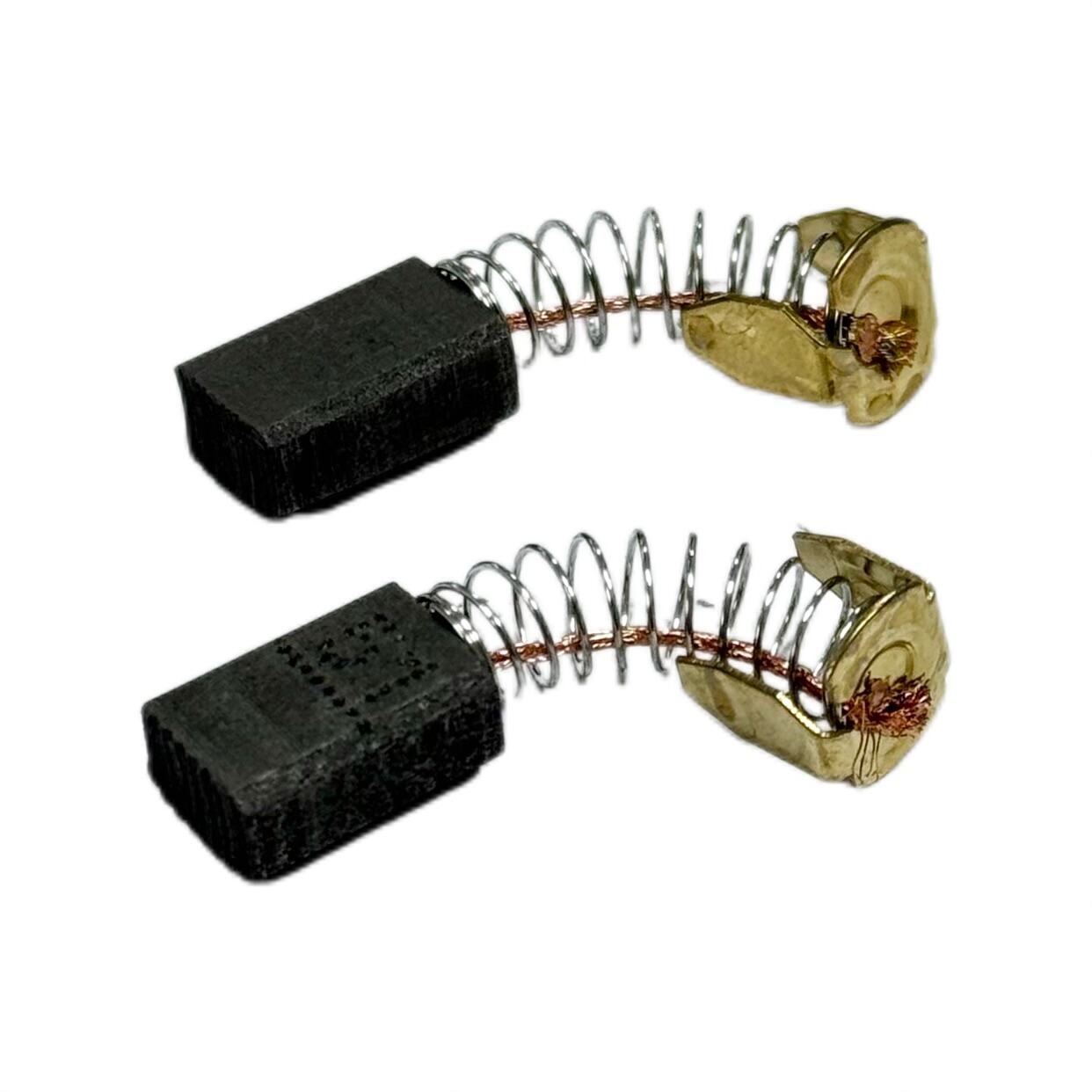

DeWalt grinder parts represent a comprehensive system of high-quality components designed to maintain and enhance the performance of DeWalt angle grinders. These essential parts include replacement grinding wheels, guard assemblies, side handles, gear cases, and brush caps, each engineered to meet DeWalt's rigorous standards for durability and precision. The components are manufactured using industrial-grade materials, ensuring longevity and reliable operation under demanding conditions. The grinding wheels, available in various grits and sizes, are reinforced with fiber mesh for enhanced safety and performance. The guard assemblies feature quick-release mechanisms for easy adjustment, while maintaining optimal protection during operation. Side handles are ergonomically designed with vibration-reducing technology, promoting user comfort during extended use. The gear cases are precision-engineered to house the internal components securely, while brush caps provide easy access for maintenance. These parts are compatible with multiple DeWalt grinder models, offering versatility and convenience for professionals and DIY enthusiasts alike.