carbon brush holder manufacturers

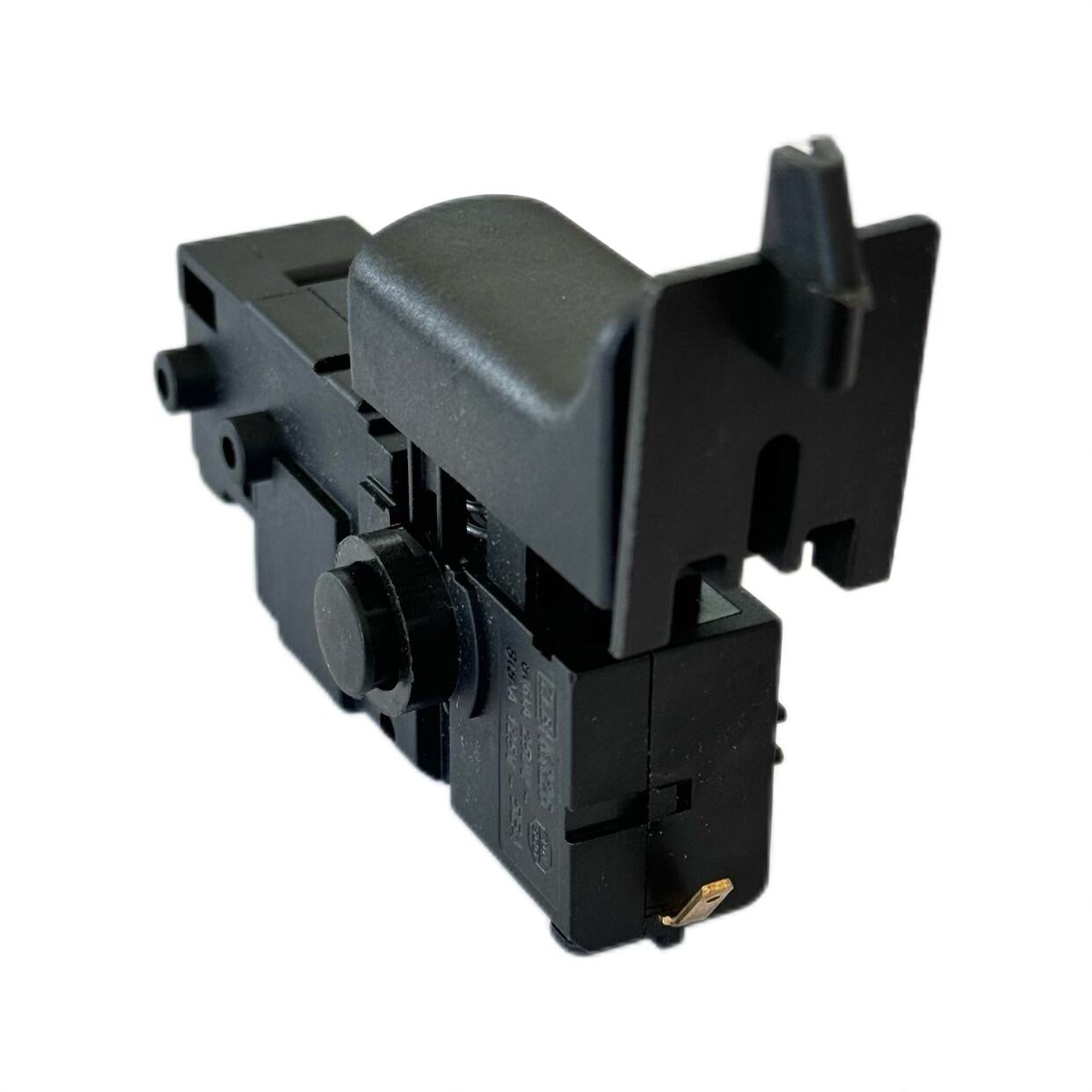

Carbon brush holder manufacturers play a vital role in the electrical machinery industry, specializing in the production of essential components that ensure reliable electrical contact in various rotating machines. These manufacturers employ cutting-edge technology and precision engineering to create holders that securely position carbon brushes against commutators or slip rings. Their products incorporate advanced features such as constant pressure spring systems, quick-release mechanisms, and protective housings that enhance performance and longevity. These manufacturers utilize high-grade materials and implement strict quality control measures throughout the production process, ensuring their products meet international standards and specifications. Their manufacturing capabilities extend from standard brush holders for industrial motors to custom-designed solutions for specialized applications in power generation, transportation, and heavy machinery. Modern carbon brush holder manufacturers integrate innovative design features that address common challenges such as brush wear monitoring, heat dissipation, and maintenance accessibility. They also provide technical support and consultation services to help clients select the most appropriate brush holder configurations for their specific applications. The industry continues to evolve with new developments in materials science and manufacturing techniques, leading to more efficient and durable products.