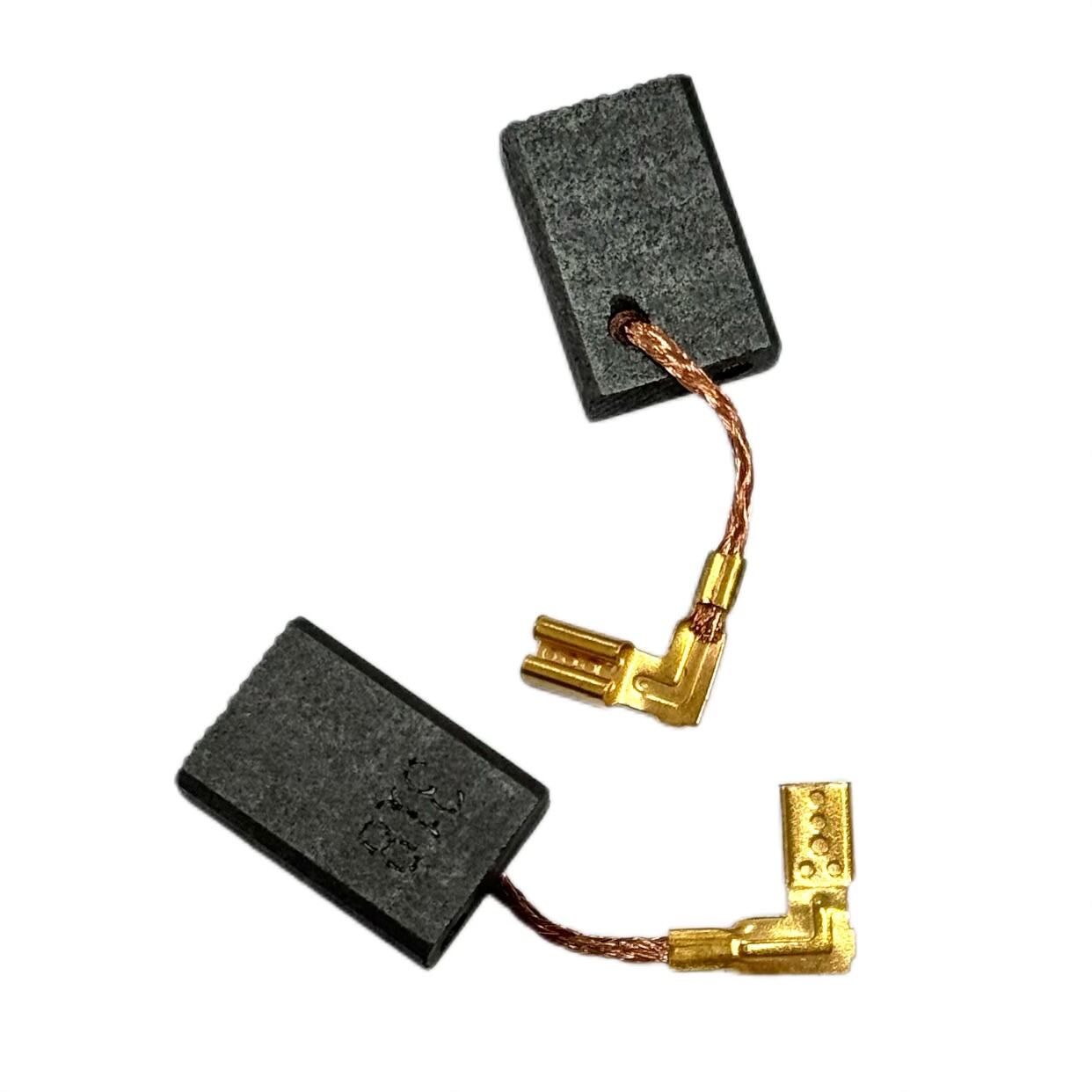

carbon brush for generator

A carbon brush for generator serves as a crucial electrical component that enables the transmission of electrical current between stationary and rotating parts in electrical machines. This essential device consists of highly conductive carbon material, engineered to maintain consistent electrical contact while minimizing wear and friction. The carbon brush effectively bridges the gap between the commutator or slip rings and the external circuit, facilitating smooth power transfer during generator operation. Modern carbon brushes incorporate advanced materials technology, featuring specialized graphite compounds and metal impregnations that enhance conductivity and durability. These brushes are designed to operate under varying temperatures and speeds, maintaining optimal performance across different operating conditions. The precise engineering of carbon brushes includes careful consideration of factors such as contact pressure, current density, and brush grade selection to ensure maximum efficiency and longevity. In generator applications, these brushes play a vital role in maintaining consistent power output by providing a reliable conducting path for electrical current. The design also incorporates self-lubricating properties that reduce maintenance requirements and extend operational life. Carbon brushes come in various sizes and specifications to accommodate different generator types and power ratings, making them versatile components in power generation systems.