Ժամանակակից անկյունային շարժիչների կառուցվածքի հասկացությունը

Արդյո՞ք դուք պրոֆեսիոնալ մետալագործ եք, թե սիրողական սարքավորումների սիրահար, անկյունային շարժիչի տարբեր մասերի տիրապետումը կարևոր է ինչպես անվտանգության, այնպես էլ արդյունավետության տեսանկյունից: Ժամանակակից անկյունային շարժիչները զգալիորեն էվոլյուցիա են կրել, ներառյալ առաջադեմ բաղադրիչներ, որոնք բարձրացնում են կատարումը՝ պահպանելով օգտագործողի անվտանգությունը: Այս համապարփակ ուղեցույցը կուսումնասիրի յուրաքանչյուր անհրաժեշտ բաղադրիչ, օգնելով ձեզ հասկանալ, թե ինչպես են այս հզոր գործիքները միասին աշխատում՝ ճշգրիտ կտրում, սղոցում և փոքր-ինչ փայլուն արդյունքներ ստանալու համար:

Անկյունային շփման սարքի հիմնական բաղադրիչներ

Էլեկտրամատակարարման և շարժիչի հանգույց

Ნებისმიერი կյունային սղոց გულში მდებარეობს მისი ძალის წყარო და ძრავის ასამბლები. ეს კუთხური შლიფმანქანის ნაწილები იმუშავებს სრული ჰარმონიით, რათა გენერირებულ იქნას საჭირო ბრუნვითი ძალა. ძრავის საცავი შეიცავს ელექტრო ძრავას, რომელიც შეიძლება питა გამოყენებულიყო სხვადასხვა წყაროდან, მათ შორის კაბელით ელექტროენერგიით, აკუმულატორებით ან შეკუმშული ჰაერით. თანამედროვე შეუხეხავი ძრავები რევოლუცია გამოიწვიეს ინდუსტრიაში, რაც უზრუნველყოფს მაღალ ეფექტურობას და ხანგრძლივ ხელსაწყოთა სიცოცხლეს.

Շարժիչի հանգույցը ներառում է պղնձե գալարումներ, ամրակ, և բարդ սառեցման համակարգեր: Բարձրակարգ մոդելները սահմանափակում են առաջացած ջերմային պաշտպանության մեխանիզմներ, որոնք կանխում են վերատաքացումը երկարատև օգտագործման ընթացքում: Հզորությունը սովորաբար տատանվում է 500Վ-ից մինչև 2500Վ մինչև մասնագիտական մոդելների համար, որը ուղղակիորեն ազդում է գործիքի հնարավորության վրա կատարելու բարդ աշխատանքներ:

Գերիների կազմույթ և վարուղական մեխանիզմ

Փոխանցման տուփը պարունակում է անկյունային շարժիչի կարևորագույն մասեր, որոնք շարժիչից հզորությունը փոխանցում են պտտվող սկավառակին: Այս համակարգը բաղկացած է ճշգրիտ կառուցված անիվներից, որոնք սովորաբար պատրաստված են լցված պողպատից և նվազեցնում են շարժիչի բարձր արագությունը՝ դարձնելով այն օգտագործելի աշխատանքային արագություն: Փոխանցման հարաբերակցությունը հաշվարկվում է հիմնականում օպտիմալ պտտման մոմենտ պահպանելու, ինչպես նաև ապահովելու համար, որ սկավառակը պտտվի ճիշտ RPM-ով՝ տարբեր կիրառությունների համար:

Ժամանակակից փոխանցման տուփերը նախագծված են բարելավված ջերմություն рассեяնալու հատկություններով և կնքված ոսպնյակներով, որոնք պահանջում են նվազագույն սպասարկում: Շարժիչային մեխանիզմը ներառում է սեղմակի արգելակումը, որը թույլ է տալիս արագ և անվտանգ սկավառակի փոխում: Գերազանց մոդելները ունեն առաջադեմ ոսպնյակային համակարգեր, որոնք նվազեցնում են թրթռոցը և երկարաձգում գործիքի ծառայողական կյանքը:

Անվտանգություն և կառավարման հատկություններ

Պաշտպանական ծածկույթներ և վահաններ

Պաշտպանական համակարգը ներկայացնում է անկյունային շարժիչի ամենակարևոր մասերից մեկը՝ օգտագործողի անվտանգության համար: Ժամանակակից պաշտպանական ծածկոցները կարգավորվող են և պատրաստված են բարձր ամրությամբ նյութերից, որոնք կարող են դիմակայել թռչող մասերի հարվածներին: Վերջին ձևավորումները թույլ են տալիս գործիքի առանց լրացուցիչ միջոցների կարգավորում՝ շահագործման ընթացքում պահպանելով կոշտ դիրք: Որոշ առաջադեմ մոդելներ ունեն ինքնաշխատ պաշտպանական ծածկոցի դիրքի կարգավորման համակարգ, որը արձագանքում է գործիքի ուղղվածությանը:

Պաշտպանական համակարգերը տարածվում են հիմնական ծածկոցից դուրս՝ ներառելով լրացուցիչ հանգույցներ թրթռոցի նվազեցմամբ և էրգոնոմիկ բռնակներ: Այս բաղադրիչները համատեղ աշխատում են՝ ապահովելով առավելագույն պաշտպանություն՝ շահագործման ընթացքում պահպանելով օպտիմալ կառավարումը: Շատ արտադրողներ իրենց պաշտպանական ծածկոցներում այժմ ներառում են թափանցիկ հատվածներ, որոնք թույլ են տալիս լավ տեսանելիություն՝ անվտանգությունը չնվազեցնելով:

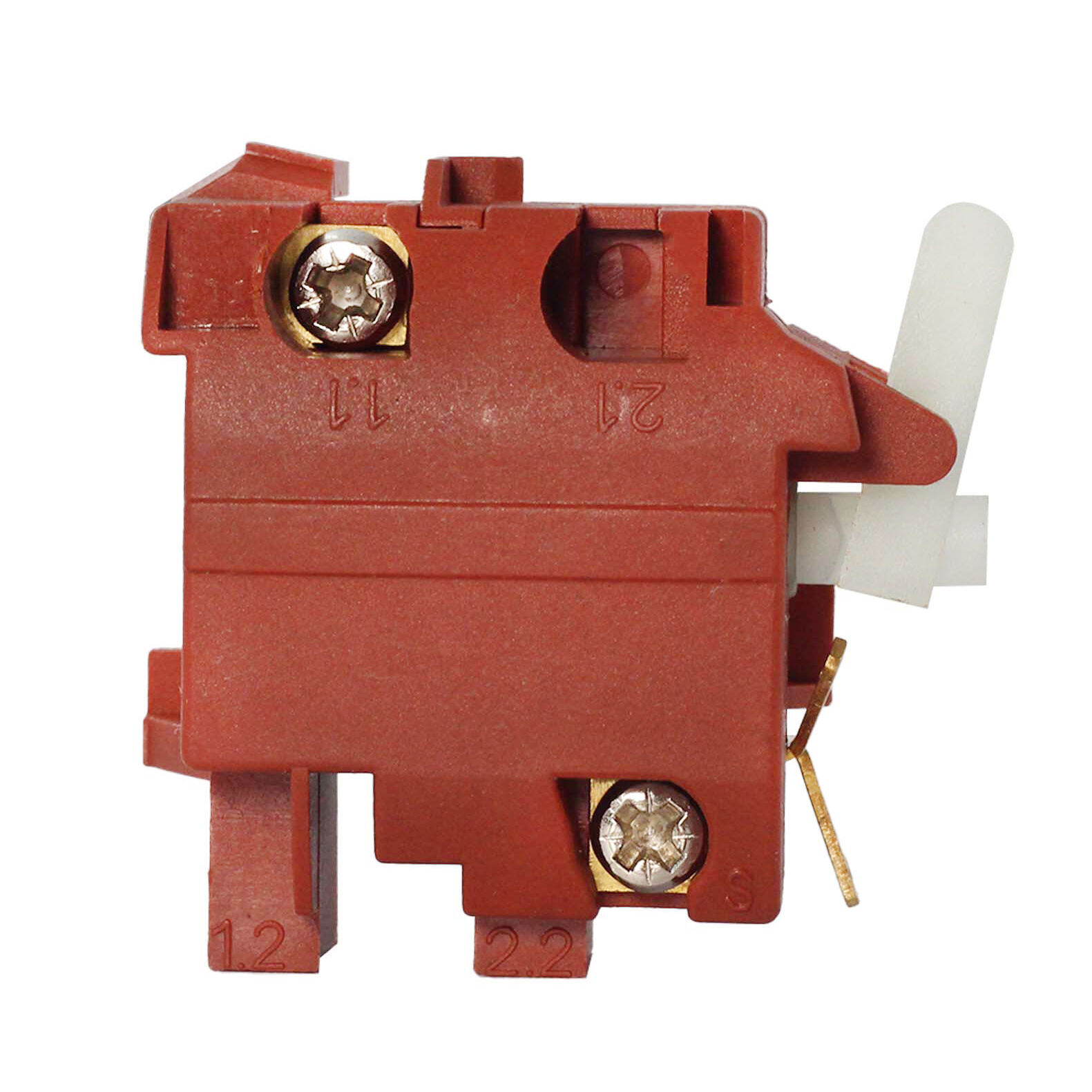

Կառավարման մեխանիզմներ և անջատիչներ

Ժամանակակից անկյունային շարժիչները ստեղծված են բարդ կառավարման մեխանիզմներով, որոնք բարձրացնում են անվտանգությունն ու օգտագործման հարմարավետությունը: Հիմնական միացման մեխանիզմը ներառում է անջատման անվտանգության ամրապնդումներ՝ պատահական միացումը կանխելու համար, իսկ կողային բռնակները ապահովում են անհրաժեշտ կայունություն աշխատանքի ընթացքում: Փոփոխական արագության կառավարումը թույլ է տալիս օգտագործողին հարմարեցնել գործիքի արագությունը կոնկրետ կիրառմանը:

Բարդ էլեկտրոնային համակարգերը իրական ժամանակում հսկում են անկյունային շարժիչի մասերը՝ կարգավորելով հզորության ելքը՝ պահպանելով արագության հաստատունությունը ծանրաբեռնվածության դեպքում: Որոշ մոդելներ ներառում են էլեկտրոնային արգելակման համակարգեր, որոնք արագ կանգնեցնում են սկավառակը, երբ գործիքը անջատվում է, ինչը զգալիորեն բարելավում է անվտանգությունը: Բռնակին և корпусին ինտեգրված հակատարբերակման համակարգերը նվազեցնում են օգտագործողի կորցրած ուժը երկարատև օգտագործման դեպքում:

Միացման և ավելցուկային սարքերի ինտերֆեյս

Շառաչ և ամրացման համակարգ

Ճոպանի հավաքակցման համակարգը համարվում է անկյունային շփման սարքի ամենակարևոր մասերից մեկը, որը ծառայում է որպես միջանկյալ օղակ սարքի և դրա տարբեր պարագների միջև: Այս համակարգը ներառում է խողովակաձև ճոպանը, ֆլանցը և ամրացնող թիթեղը, որոնք ճշգրիտ կերպով են ստեղծված՝ ապահովելու սղոցման սկավառակների, կտրող անիվների և այլ պարագների ամուր ամրացումը: Ժամանակակից արագ փոխարինման համակարգերը թույլ են տալիս սկավառակները առանց գործիքների փոխել՝ պահպանելով առավելագույն անվտանգություն:

Գերազանց ամրացման համակարգերը ներառում են ավտոմատ հավասարակշռման մեխանիզմներ, որոնք նվազեցնում են թրթռոցը և բարելավում են ճշգրտությունը: Ճոպանի խողովակի չափսը և կառուցվածքը տարբերվում են մոդելների ընտրությամբ, որտեղ տարածված չափերն են M14-ը և 5/8-11 UNC-ն: Այս ստանդարտները հասկանալը կարևոր է համատեղելի պարագներ ընտրելու համար:

Սկավառակներ և պարագներ

Անկյունային շարժիչների տարատեսակները հնարավորություն են տալիս օգտագործել տարբեր ապակցումներ: Լրակազմի ինտերֆեյսը հարմարեցված է տարբեր տեսակի սկավառակների համար, ներառյալ շփման սկավառակներ, կտրող սկավառակներ, սեղմիչ մանգաղներ և փայլատվող պադեր: Յուրաքանչյուր ապակցում պահանջում է հատուկ անկյունային շարժիչի մասեր ճիշտ տեղադրման և աշխատանքի համար:

Ժամանակակից ապակցումները օգտագործում են առաջադեմ նյութեր և կառուցվածքներ, որոնք առավելագույնի հասցնում են արդյունավետությունը՝ պահպանելով անվտանգությունը: Ալմաստե ծայրամասերով կտրող անիվները, կերամիկական շփման սկավառակները և կոմպոզիտային թևավոր սկավառակները ապակցումների տեխնոլոգիայի վերջին նորարարություններն են: Ինտերֆեյսի կառուցվածքը երաշխավորում է, որ այս ապակցումները պահպանում են ճիշտ համաչափությունը և հավասարակշռությունը աշխատանքի ընթացքում:

Պահպանման և խնամքի մասեր

Ծառայելի մասեր

Անկյունային շարժիչի մասերի սովորական սպասարկումը ապահովում է օպտիմալ աշխատանք և երկար ծառայողական ժամկետ: Հիմնական սպասարկվող մասերին են դասվում ածխածին սեղմակները, լագերները և սառեցման օդանցքերը: Ժամանակակից կոնստրուկցիաները թույլ են տալիս հեշտ մուտք ապահովել այս մասերին՝ մասնակի առանց գործիքների սպասարկման սալիկների միջոցով: Վերջին մոդելները ստանդարտ ներառում են ցուցիչ համակարգեր, որոնք տեղեկացնում են օգտատիրոջը, երբ անհրաժեշտ է սպասարկում:

Սառեցման համակարգերը զարգացել են՝ ներառելով առաջադեմ օդի ուղղորդման և ջերմությունը рассեյացնելու մեխանիզմներ: Այս համակարգերը պաշտպանում են ներքին մասերը՝ պահպանելով կայուն աշխատանք ծանր շահագործման պայմաններում: Որոշ մասնագիտական մոդելներ ներառում են ախտորոշման համակարգեր, որոնք հսկում են կարևորագույն մասերի վիճակը:

Փոշու կառավարման համակարգեր

Արդյունաբերական անկյունային շարժիչներում փոշու արդյունավետ կառավարումը դարձել է ավելի կարևոր: Առաջադեմ փոշու հավաքման համակարգերը հարթ ձևով ինտեգրվում են անկյունային շարժիչի մյուս մասերի հետ՝ մասնիկները աղբյուրի մոտ հավաքելու համար: Այս համակարգերը ներառում են հատուկ պաշտպանիչներ արտահոսքի նեղուցներով և կնքված լագերներ, որոնք կանխում են փոշու ներթափանցումը:

Ամենավերջին փոշու կառավարման լուծումները ներառում են ինքնաշխատ մաքրման մեխանիզմներ և համատեղելիություն տարբեր փոշեծաղիկների հետ: Որոշ մոդելներ ստվերաչափային սենսորներ են ներառում, որոնք հսկում են փոշու մակարդակը և համապատասխանաբար կարգավորում են արտածման արդյունավետությունը: Այս համակարգերը ոչ միայն պաշտպանում են գործիքի ներքին մասերը, այլ նաև նպաստում ավելի անվտանգ աշխատանքային միջավայրի ստեղծմանը:

Հաճախ տրվող հարցեր

Որքան հաճախ պետք է ստուգվեն անկյունային շարժիչի մասերը?

Մասնագետ օգտատերերը պետք է ստուգեն անկյունային շարժիչի մասերը յուրաքանչյուր օգտագործումից առաջ՝ ամենաքիչը ամսեկան մեկ անգամ հիմնական ստուգում իրականացնելով: Ստուգման հիմնական ուղղություններն են պաշտպանի ամբողջականությունը, սնուցման կabel-ի վիճակը, մաքուրի մաշվածությունը և ոսպնյակների հարթ աշխատանքը: Պարբերական ստուգումները օգնում են կանխել անսպասելի խափանումները և ապահովում են անվտանգ շահագործումը:

Ի՞նչ են անկյունային շարժիչի ամենատարածված մաշված մասերը

Անկյունային շարժիչի ամենահաճախ փոխարինվող մասերին են պատկանում ածխածին մաքուրները, շփման սկավառակները, հենարանային պադերը և սնուցման կabel-ները: Մաշվածության աստիճանը կախված է օգտագործման ձևից և աշխատանքային պայմաններից: Մասնագետ օգտատերերը սովորաբար յուրաքանչյուր 100-200 ժամ աշխատանքից հետո փոխում են ածխածին մաքուրները:

Կարո՞ղ եմ բարձրացնել անկյունային շարժիչի անվտանգության հատկանիշները

Շատ ժամանակակից անկյունային շարժիչների մասեր նախատեսված են հետևյալ տեղադրման համար: Օգտատերերը հաճախ կարող են անցնել ավելի առաջադեմ պաշտպանական համակարգերին, լրացուցիչ հանգույցներին՝ բարելավված թրթռացման վերահսկմամբ, և փոշու կառավարման ավելի լավ լուծումներին: Այնուամենայնիվ, կարևոր է օգտագործել միայն արտադրողի կողմից հաստատված մոդեռնացումներ՝ անվտանգության վավերագրումը պահպանելու համար:

Ի՞նչն է որոշում փոխարինման մասերի համատեղելիությունը

Համատեղելիությունը կախված է շարժիչի մոդելից, չափի դասից և արտադրության սպեցիֆիկացիաներից: Կարևոր գործոններն են լարման հաշվարկները, արագության սպեցիֆիկացիաները, ամրացման խցանների չափերը և պաշտպանի չափերը: Միշտ խորհուրդ է տրվում ծանոթանալ արտադրողի փաստաթղթերին՝ ընտրելու անկյունային շարժիչի մասերի փոխարինումը՝ ճիշտ համընկնում և անվտանգ շահագործում ապահովելու համար: