Essential Components of Modern Angle Grinders

Angle grinders represent indispensable power tools in workshops worldwide, consisting of multiple angle grinder parts working together seamlessly. Understanding these components is crucial for both professional craftsmen and DIY enthusiasts who rely on these versatile tools for cutting, grinding, and polishing tasks. From the motor assembly to the grinding disc, each element plays a vital role in the tool's performance and longevity.

Modern angle grinders have evolved significantly, incorporating advanced features and durability-enhancing components. The interplay between various angle grinder parts ensures smooth operation while maintaining user safety. Whether you're working with metal, stone, or concrete, knowing your tool's anatomy helps maximize its potential and extend its service life.

Core Components and Their Functions

Power System and Motor Assembly

The heart of any angle grinder lies in its motor assembly. This crucial component typically consists of an electric motor, armature, and field coils. The motor converts electrical energy into mechanical power, driving the spindle that holds the grinding disc. High-quality angle grinder parts in the motor assembly include copper windings, carbon brushes, and precision bearings that ensure efficient power transfer and smooth operation.

Modern angle grinders feature advanced motor designs with overload protection and soft-start mechanisms. These protective elements prevent damage during heavy-duty applications and extend the tool's lifespan. The motor housing itself is engineered with cooling vents to dissipate heat effectively during prolonged use.

Gear System and Drive Mechanism

The gear mechanism transfers power from the motor to the spindle, maintaining optimal speed and torque. This system consists of precisely machined gears, typically made from hardened steel. The gear housing contains these angle grinder parts and keeps them properly lubricated. Regular maintenance of the gear system is essential for preventing wear and ensuring consistent performance.

Advanced models incorporate spiral bevel gears that reduce noise and vibration while improving power transfer efficiency. The gear ratio is carefully calculated to provide the ideal balance between speed and torque for various applications.

Safety Features and Control Elements

Guard and Shield Components

Safety features form an integral part of modern angle grinders. The wheel guard, one of the most vital angle grinder parts, protects users from sparks and debris. Made from durable materials like reinforced plastic or metal, these guards are adjustable to provide optimal protection regardless of the working angle.

Additional safety components include the side handle mount and vibration-dampening systems. These elements work together to provide better control and reduce operator fatigue during extended use. The guard mounting mechanism allows for quick adjustments while maintaining secure positioning during operation.

Switch Mechanisms and Controls

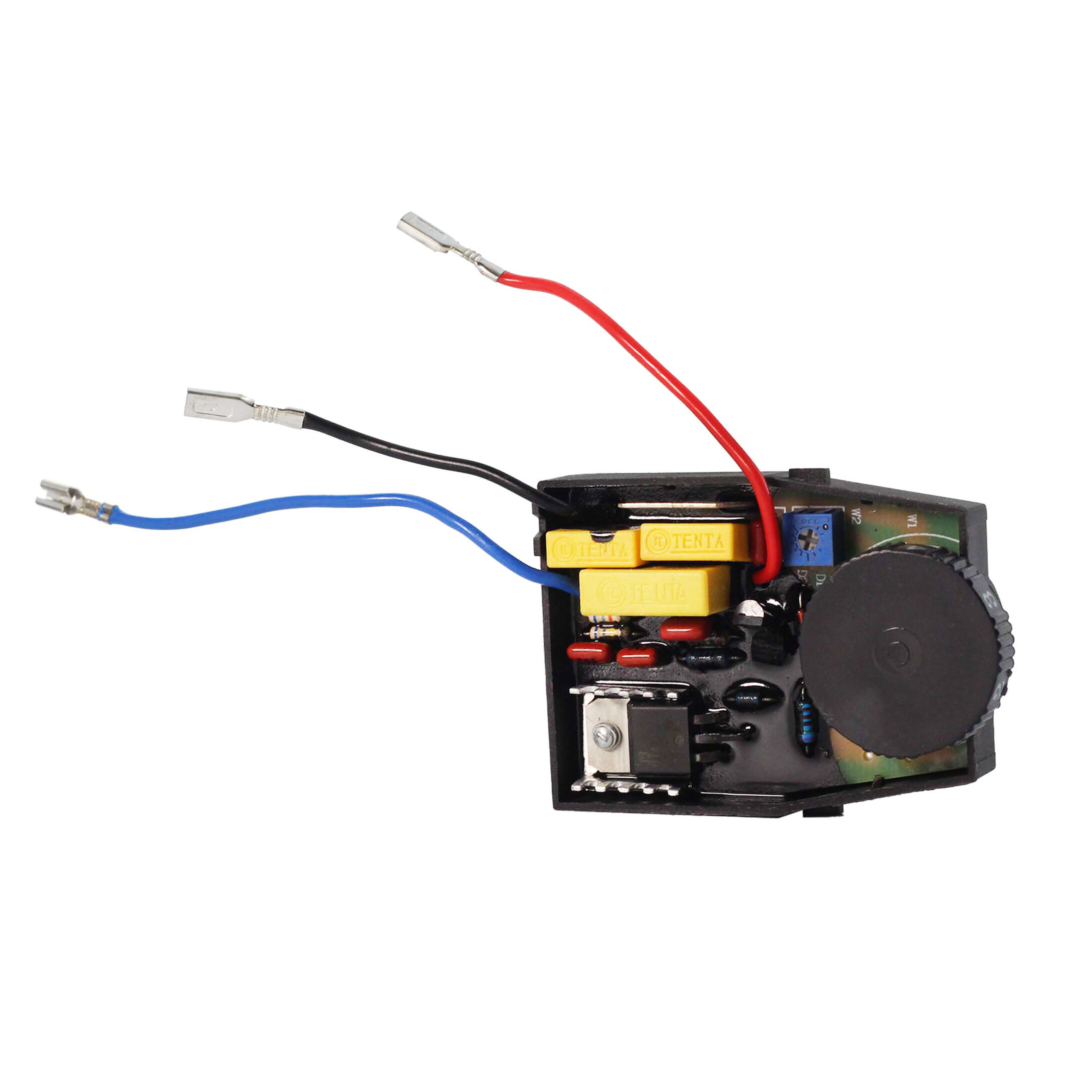

The control system includes several sophisticated angle grinder parts designed for safe operation. The main power switch often incorporates a dead-man function, immediately stopping the tool when released. Variable speed controls allow users to match the tool's speed to specific applications and materials.

Modern grinders also feature electronic safety systems like restart protection, which prevents accidental startup after power interruptions. The speed control module maintains consistent RPM under varying loads, ensuring optimal cutting and grinding performance.

Maintenance and Care Procedures

Regular Inspection Protocol

Maintaining angle grinder parts requires systematic inspection and care. Begin by checking the power cord for any damage or wear. Examine the carbon brushes periodically for wear and replace them when they reach their wear limit. This preventive maintenance helps avoid unexpected breakdowns and ensures consistent performance.

Inspect the gear housing for proper lubrication and any signs of metal particles that might indicate excessive wear. The spindle and flange system should be checked for alignment and secure mounting. Regular cleaning of ventilation slots prevents dust accumulation and maintains proper cooling.

Replacement and Repair Guidelines

When replacing angle grinder parts, always use manufacturer-recommended components to maintain tool performance and safety. Common replacement items include grinding discs, carbon brushes, and wheel guards. Follow proper installation procedures and torque specifications when replacing these components.

For more complex repairs involving the motor or gear system, consult professional service technicians. They have the expertise and tools necessary to properly diagnose and repair internal angle grinder parts without compromising the tool's integrity or safety features.

Frequently Asked Questions

How often should angle grinder parts be inspected?

Regular inspection of angle grinder parts should occur every 40-50 hours of use or monthly, whichever comes first. However, heavy users should perform quick visual inspections before each use and conduct thorough checks more frequently.

What are signs that carbon brushes need replacement?

Common indicators include increased sparking from the motor housing, inconsistent power output, or difficulty starting the tool. Most carbon brushes should be replaced when they wear down to about 1/4 of their original size.

How can I extend the life of my angle grinder's bearings?

To maximize bearing life, avoid overloading the tool, ensure proper lubrication according to manufacturer specifications, and keep the tool clean and dry. Regular maintenance of these crucial angle grinder parts significantly extends their service life.

When should I replace the gear housing lubricant?

The gear housing lubricant should typically be replaced every 100-150 hours of use or annually. However, if you notice increased noise or heat from the gear housing, immediate inspection and potential lubrication replacement may be necessary.